Optical Sorting & Image-Based Impurity Removal

Advanced image-sensing technology detects and removes any onion roots or unwanted impurities.

QC Checks:

- Foreign Matter Identification: Ensuring purity through AI-based optical sorting systems.

- Density & Color Uniformity Testing: Maintaining consistent product quality.

Secure Secondary Packaging for Global Shipping

Secure Secondary Packaging for Global Shipping

The polybags are further packed into durable paper bags or corrugated cartons, customized according to export and customer requirements.

Hygienic Moisture-Free Packaging (Food-Grade)

Hygienic Moisture-Free Packaging (Food-Grade)

The finished dehydrated onion kibbled is carefully packed in high-quality, moisture-resistant, food-grade, two-layer polybags to preserve freshness and prevent contamination.

Final Manual Sorting for Ultimate Purity

Final Manual Sorting for Ultimate Purity

A final manual sorting process by skilled quality control personnel ensures that any remaining impurities, foreign bodies, or discolored pieces are removed.

Metal Detection & Magnetic Screening for Safety

Metal Detection & Magnetic Screening for Safety

The sorted kibbled onions pass through a high-intensity rare-earth magnet and metal detector to eliminate any metallic contaminants.

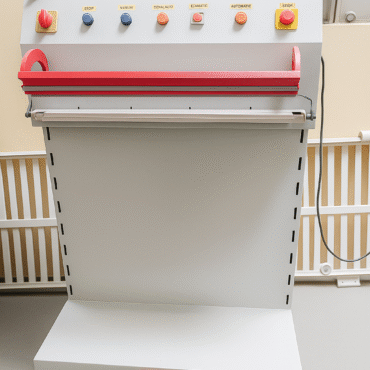

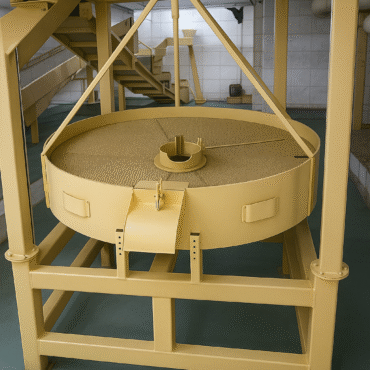

Hulling & Air Aspiration for Skin and Root Removal

Hulling & Air Aspiration for Skin and Root Removal

The cooled onion slices enter a high-efficiency huller machine, which separates kapcha (fine particles), kibbled onions, and skins.

Controlled Cooling & Conditioning

Controlled Cooling & Conditioning

Dehydrated onion slices pass through a cold-drying chamber, allowing gradual cooling in a controlled environment to prevent rehydration and preserve flavor.